Hydroxyethyl methyl cellulose with CAS 9032-42-2

Basic Info

Model No.: 9032422

Product Description

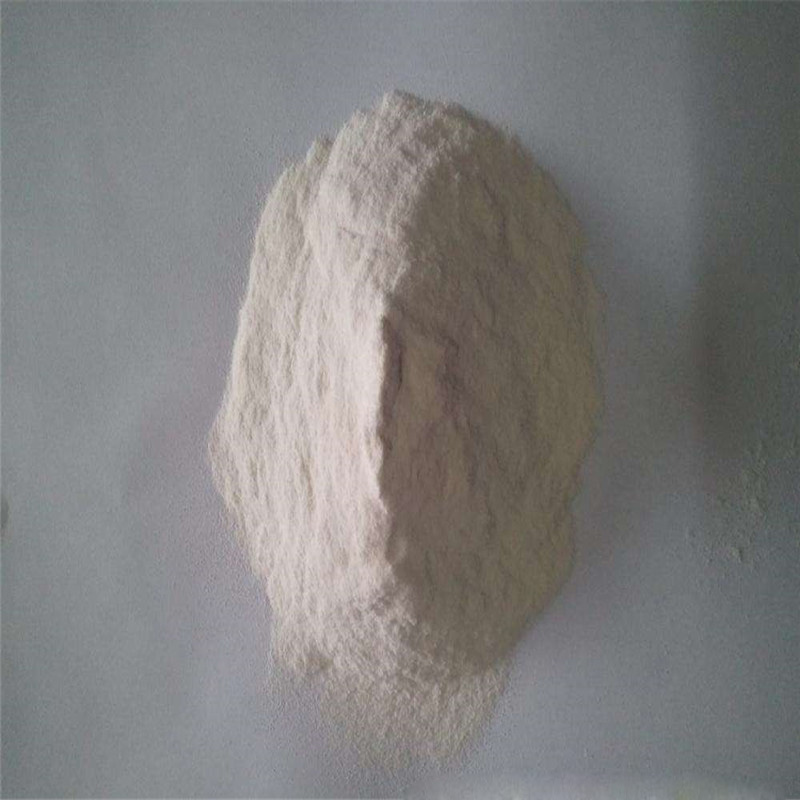

Hydroxyethyl methyl cellulose (HEMC) 9032-42-2

Hydroxyethyl methyl cellulose (CAS:9032-42-2), also known as HEMC, 2-Hydroxyethyl methyl cellulose is white powder. Salt resistance of Hydroxyethyl methyl cellulose is better than unmodified polymer, and the gel temperature of Hydroxyethyl methyl cellulose is also relatively high MC.

Synonyms:

2-Hydroxyethyl methyl cellulose; HYDROXYETHYL METHYL CELLULOSE; CELLULOSE METHYL HYDROXYETHYL ETHER; METHYL HYDROXYETHYL CELLULOSE; Cellulose,2-hydroxyethylmethylether; 'Tylose'® MH 300; Hydroxythyl Methyl Cellulose; HydroxythylMethylCellulose(Hemc)

Property:

CAS:9032-42-2

Density:1.28-1.30 g/cm3 (20℃)

storage temp.:Store below +30°C.

solubility:H2O: 20 mg/mL, soluble

Fluid cement base matting mortar

1. Improve the uniformity, make it easier to apply the plaster, and improve the ability to resist vertical flow. Enhance fluidity and pumpability to improve work efficiency.

2. High water retention, extended working time of mortar, improved working efficiency, and helped the mortar form high mechanical strength during solidification.

3. Control the infiltration of air, so as to eliminate the micro-cracks in the coating and form the ideal smooth surface.

Fluid gypsum plaster and gypsum products

1. Improve the uniformity, make it easier to apply the plaster, and improve the anti-vertical flow capacity to enhance the fluidity and pumpability. Thus improve work efficiency.

2. High water retention, extended working time of mortar, and produced high mechanical strength during solidification.

3. The high quality surface coating is formed by controlling the uniform consistency of mortar.

The stallion masonry mortar

1. Enhance the adhesion to the masonry surface and enhance water retention, so as to improve the strength of mortar.

2. Improve the lubrication and plasticity so as to improve the construction performance.

The overhaulplate fills the seam material

1. Excellent water retention, which can prolong cooling time and improve working efficiency. High lubricity makes application easier and smooth.

2. Improve the anti-contraction and anti-crack properties, and improve the surface quality.

3. Provide smooth and even texture, and make the bonding surface more adhesive.

Foremost ceramic adhesive

1. Make dry mixing ingredients easy to mix and avoid clumping, thus saving working time. As application is faster and more effective, it can improve construction performance and reduce costs.

2. The brick sticking efficiency is improved by extending the cooling time. Provides excellent adhesion effect.

The charges flow across the surface material

1. Provide viscosity, which can be used as an anti-precipitation agent.

2. Enhance fluidity and pumpability, so as to improve the efficiency of floor paving.

3. Control water retention, so as to greatly reduce cracking and shrinkage.

Overhaul water-based paint and paint remover

Storage life is extended by preventing solid precipitation. It has excellent compatibility with other components and high biostability.

2. Fast dissolution without lumps helps to simplify the mixing process. Cold water dispersing model product, can make mixing more rapid and convenient, and does not produce clumps.

3. Produce favorable flow characteristics, including low splash and good leveling, to ensure good surface finish and prevent paint from sagging.

4. Enhance the viscosity of water-based paint remover and organic solvent paint remover, so that the paint remover will not flow out of the workpiece surface.

The fibers extrude into shaped concrete plates

1. Enhance the machinability of the extrusion products, with high bonding strength and lubricity.

2. Improve the wet strength and adhesion after extrusion of the plate.

Packing:

Double bag, outer composite paper bag, inner polyethylene film bag, each bag net weight 20kg or 25kg.

Storage and transportation:

Store in the indoor ventilated and dry place, pay attention to moisture-proof. Prevent rain and sun during transportation.

1. The product is in danger of dust explosion. When handling in large quantities or in bulk, be careful to avoid dust deposition and suspension in the air. Do not approach heat, Mars, flame and static electricity.

2. Avoid methyl cellulose powder and contact with eyes. Wear filter mask and safety goggles when operating.

3. The product is slippery when it is wet. The methylcellulose powder should be cleaned timely and anti-skid treatment should be done.

Other related items of our company:

1. Basic Organic Chemicals

2. Inorganic Chemicals

3. Pharmaceutical Intermediates

4. Daily Chemicals

5. Active Pharmaceutical Ingredients

Product Categories : Chemical Auxiliary Agents